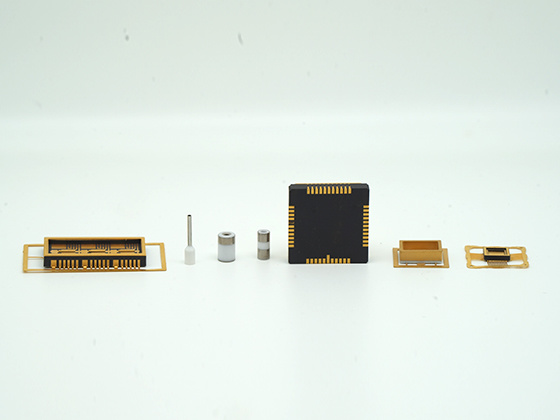

Circuit Board Series/ The Ceramic Thin Film Substrate Used For Integrated Circuit.

|

Brand Name |

MC |

|

Certification |

ROHS,REACH |

|

Minimum Order Quantity |

Negotiation |

|

Price |

Negotiation |

|

Packaging Details |

Inner vacuum packaging, outside carton. |

|

Delivery Time |

15-45 days |

|

Payment Terms |

T/T, L/C, D/P. D/A, West Union etcs. |

|

Place of Origin |

Hunan,China |

keyword:

New Energy Ceramic Thermostat Ceramic

Circuit Board Series/ The Ceramic Thin Film Substrate Used For Integrated Circuit.

Product description

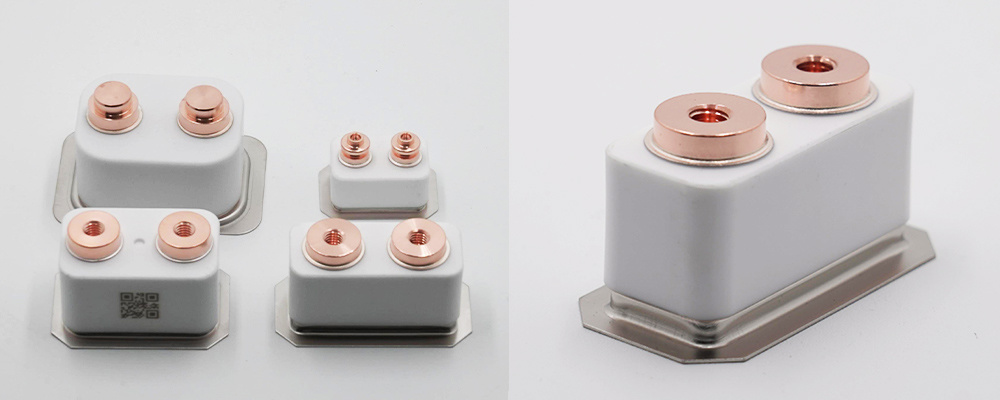

1.Description: Black ceramics with low melting point which used for glass substrate integrated circuit, is one of the main forms of integrated circuit package (full ceramic package, black ceramics low melting glass packaging, plastic packaging)There liability and production cost are between ceramic and plastic packaging.It has the characteristics of good light shielding performance, good protection for photosensitive semiconductor device , good heat dissipation.The thin film substrate used for integrated circuit, with accurate size, fine surface condition, good electrical performance which was widely used in civiland military fields.

2.Feature Advantages:

① Higher thermal conductivity and heat resistance.

② Smaller coefficient of thermal expansion.

③ Stronger, lower resistance metal film alumina ceramic circuit boards.

④ Good electronic insulation.

⑤ Low high frequency losses.

⑥ Excellent thermal stability.

4.Process Flows:

5.Order Flow Steps : Inquiry ---Drawing Quotation --- Place an order --- Production --- Delivery

6.Our aim market

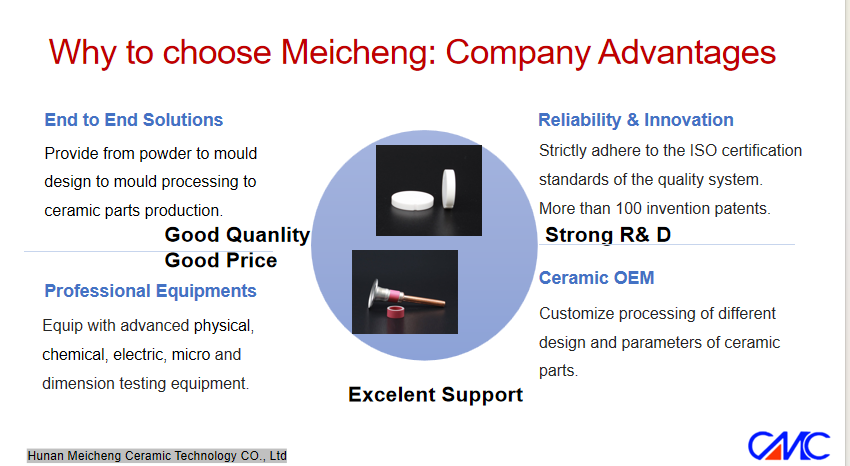

Hunan Meicheng Electronic Ceramic Co.,Ltd is one of the most leading and advanced ceramic component companies in Hunan China, Brand name "MC" is formed almost 15 years . Our products are widely used in new energy car, power pile, electricity and other fields. We are an ISO9001: 2015 certified manufacturer of Alumina, Zirconia and Steatite parts.

FAQ

The name of advanced ceramics?

In order to distinguish traditional ceramics, the later development of modern ceramics is called advanced ceramics (Advanced Ceramics), also known as special ceramics (Special Ceramics), engineering ceramics (Engineering ceramics), fine ceramics (Fine Ceramics), New ceramics, industrial ceramics (industry ceramics), high technology ceramics and high performance ceramics are also classified as structural ceramics or functional ceramics.

Why Use Advanced Ceramics?

Because advanced ceramics have the advantages that cannot be compared with metal and plastic materials: high hardness, high wear resistance, high strength, not easy to deform, corrosion resistance, oxidation resistance, good stability, no reaction with other substances, high temperature resistance, good insulation, no magnetic and so on.

In the process of development of science and technology, in the development of aerospace industry, we hope that the performance of a material must meet several conditions. It is more wear-resistant than metal, can withstand high temperatures of about 2,000 degrees, low density, the lighter the better, but from many metal materials (steel, copper, aluminium, silver and gold) and plastic materials. we can not find such materials. The scientific community has developed advanced ceramics with these excellent properties, the "new world" of materials.

For example, in high-power electronic devices, we hope to have a material with good insulation and high temperature resistance of 600 degrees. But we know that the general metal is conductive, plastic materials are generally insulating, but more than a hundred degrees softened, obviously not. We use the alumina ceramic substrate or aluminium nitride ceramic substrate, silicon nitride ceramic substrate in advanced ceramics, which perfectly meets the need of insulation and high temperature resistance.

Why are advanced ceramic materials so expensive?

1) Advanced ceramic materials generally used in industry, there are some ceramic materials that do not exist in nature (such as silicon nitride, aluminum nitride ceramics), which are manufactured by chemical combination;

Higher;

2) The powder manufactured must be purified several times, the purity of the powder is very high, and the alumina ceramics require many requirements to reach more than 95%, and some requirements to reach 99% or more.

3) The proportion of product requirements is precise and strict, although the purity of many ceramic products does not reach 99%, but more than 99% of the powder is added to facilitate sintering of the formula powder, so that the sintering of ceramic products better performance.

4)The powder requires fine, the zirconia powder is about 0.0005mm, and the daily ceramics are about 1-2mm;

5) The sintering temperature is high, the sintering temperature of alumina ceramics is about 1600 degrees, and the requirements for high-temperature materials and heating elements of the kin are higher, and the energy consumption of electric gas is also high;

6) precision machining,to use diamond tools and precision machine tools, ceramic hardness,machining slowly;

7) From powder mixing, making molds, remolding, sintering, processing to producing finished products, there are many processes, long production time, and it is also the main reason for high prices;

8) Precision ceramics is also used in the case of metal and plastic can not be competent, from the aerospace military development to industrial use, is still a high-grade material, the price is much higher than ordinary metal. At present, the application of advanced ceramic products is not too

extensive, and there are not many people who understand it. As the use becomes more and more extensive, the production scale becomes larger and larger, and the process becomes more and more mature, the price will become more and more affordable.

How to reduce the price of ceramic products?

There are several ways to reduce product prices:

1)can increase the number;

2) Reduced accuracy;

3) Or change the product structure, so that the product is convenient for molding, sintering and processing, and reduce the scrap rate;

4) Choose lower priced materials such as alumina;

Related products

Advisory Message

To: Renqiu Jinshi Welding Machine Co.,Ltd