Ceramic Mold Customization

December 2017, Xinmeida Mold Manufacturing Co., Ltd. A wholly-owned subsidiary of MC Group.The design, processing and debugging of molds are all completed by ourselves.

Custom ceramic molds typically involve the following steps:

1.Design Requirements Confirmation: The process begins with clearly defining the requirements for the ceramic mold. This includes specifying dimensions, shape, intended use, and any special features or considerations.

2.Material Selection: Choosing the appropriate ceramic material for the mold is crucial. Common options include plaster, silicone, quartz, zirconia oxide, depending on factors such as mold complexity, durability requirements, and the type of ceramics to be molded.

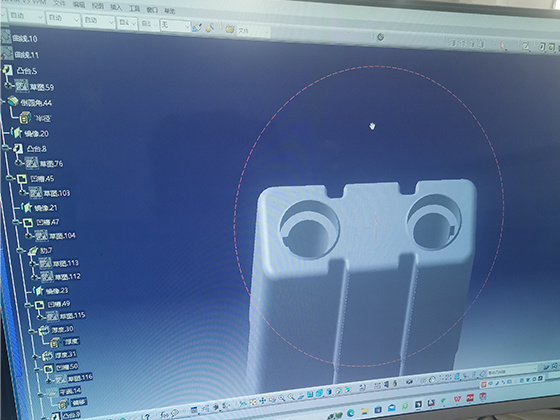

3.Model Creation: Creating a prototype or model of the mold design is the next step. This can be done through using Computer-Aided Design (CAD) software for precise digital modeling.

4.Mold Making: This process may involve techniques such as casting, pressing, or machining depending on the chosen material and complexity of the mold design.

5.Testing and Adjustments: The completed mold is then tested to ensure it meets the required specifications. Adjustments may be made to refine the mold's performance or address any issues identified during testing.

Each of these steps requires expertise in ceramic materials, mold-making techniques, and sometimes specialized equipment. Collaboration with experienced ceramic mold makers or manufacturers is often essential to ensure the successful customization and production of ceramic molds.